Marine Rubber Airbags Boat Lift Air Bags Repair Materials For Ship

Launching

Description

Marine rubber airbags are durable and versatile products used in

various marine industries. Designed to withstand high pressure,

these airbags are commonly used for ship launching, docking, and

salvaging operations.

These airbags are made from high-quality rubber material, ensuring

their resistance to abrasion, aging, and seawater corrosion. They

are also equipped with reinforced synthetic tire cord layers for

added strength and stability. The airbags come in different sizes

and types, allowing for customization to suit specific

requirements.

Marine rubber airbags offer significant advantages over traditional

ship launching methods. They provide an efficient and

cost-effective solution, reducing the need for heavy machinery and

complicated operations. Additionally, these airbags have a compact

design, making them easy to transport and deploy.

In ship launching applications, marine rubber airbags are placed

beneath the vessel to lift it out of the water for launch. Their

excellent load-bearing capacity and uniform pressure distribution

ensure a smooth and safe process. Similarly, in ship docking and

salvaging operations, these airbags provide reliable support and

stability.

Specifications

| Product Name | Marine Rubber Airbags Boat Lift Air Bags Repair Materials For Ship

Launching |

| Keywords | Marine Airbags for Launching |

| Material | 100% High Grade Natural Rubber (NR) |

| Dimensions | Diameter 0.5m - 3.0m, Length 3.0m - 28.0m, or As Request |

| Working Pressure | 0.05-0.25MPA |

| Technology | High Pressure, Overall Winding, Explosion-proof |

| Metal Parts | Q355 / SS304 / SS316 |

| OEM | Supported |

| MOQ | 1 |

| Repair Tools | Electric Heating Plate, Repair Materials, Glue, Free of Charge |

| Standard | ISO14409:2011 |

| Certificate | ABS, BV, KR, LR, GL, NK, RINA, DNV, RMRS |

| Package | Pallets, Wooden Cases |

| Service Life | 20 Years |

| Warranty | 36 Months |

| Diameter | Working Pressure | Working Height | Bearing Capacity |

| KN/m | Ton/m |

| D=1.0m | 0.14Mpa | 0.6m | 87.96 | 8.98 |

| 0.5m | 109.96 | 11.22 |

| 0.4m | 131.95 | 13.46 |

| D=1.2m | 0.12Mpa | 0.7m | 94.25 | 9.62 |

| 0.6m | 113.10 | 11.54 |

| 0.5m | 131.95 | 13.46 |

| 0.4m | 150.80 | 15.39 |

| D=1.5m | 0.10Mpa | 0.9m | 94.25 | 9.62 |

| 0.8m | 109.96 | 11.22 |

| 0.7m | 125.66 | 12.82 |

| 0.6m | 141.37 | 14.43 |

| 0.5m | 157.08 | 16.03 |

| D=1.8m | 0.09Mpa | 1.1m | 98.96 | 10.10 |

| 1.0m | 113.10 | 11.54 |

| 0.9m | 127.33 | 12.98 |

| 0.8m | 141.37 | 14.43 |

| 0.7m | 155.51 | 15.87 |

| 0.6m | 169.65 | 17.31 |

| D=2.0m | 0.08Mpa | 1.2m | 100.53 | 10.26 |

| 1.1m | 113.10 | 11.54 |

| 1.0m | 125.66 | 12.82 |

| 0.9m | 138.23 | 14.11 |

| 0.8m | 150.80 | 15.39 |

| 0.7m | 163.36 | 16.67 |

| 0.6m | 175.93 | 17.95 |

| * Other size can be provided follow client's requirements. |

Features

High durability

Marine rubber airbags are made from high-quality rubber material,

ensuring their resistance to abrasion, aging, and corrosion from

seawater. This durability allows the airbags to withstand the harsh

marine environment and ensures their long-lasting performance.

Versatility

These airbags are designed for various marine applications such as

ship launching, docking, and salvaging operations. Their

versatility makes them suitable for different types and sizes of

vessels, providing a flexible solution for marine industry needs.

Excellent load bearing capacity

Marine rubber airbags are engineered to have exceptional

load-bearing capacity, enabling them to lift heavy vessels out of

the water for ship launching. Their uniform pressure distribution

ensures a stable and safe lifting process without causing damage to

the vessels.

Cost effectiveness and efficiency

Compared to traditional ship launching methods that require heavy

machinery and complicated procedures, marine rubber airbags offer a

more cost effective and efficient solution. They eliminate the need

for extensive infrastructure and reduce the operational time,

contributing to overall cost savings and increased productivity.

Applications

● Ship launching

● Docking

● Salvaging operations

● Offshore platform installation

● Underwater pipeline installation

Advantages

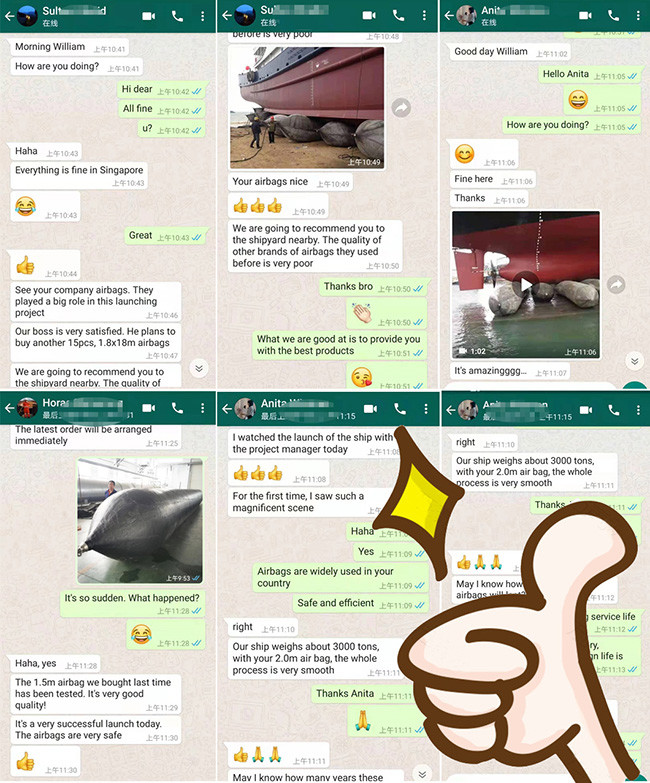

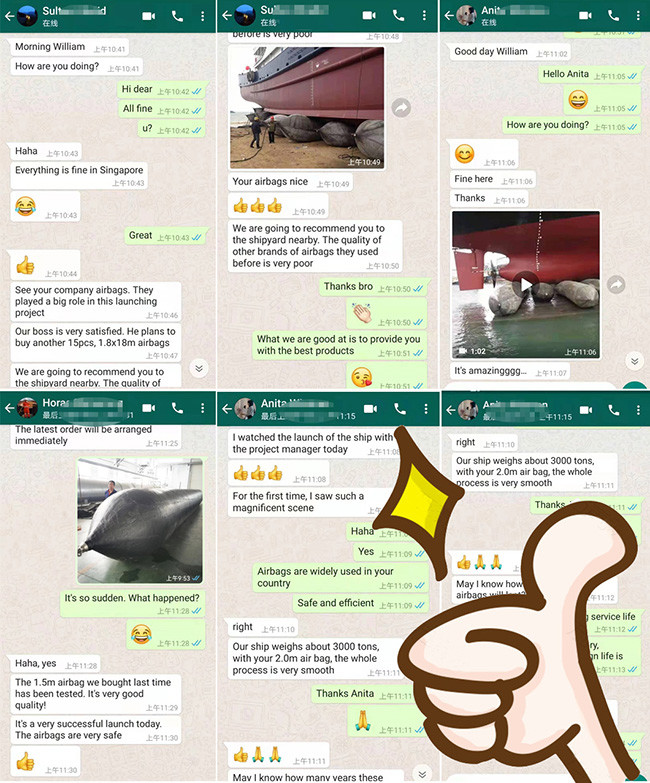

Extensive manufacturing experience

With over 30 years of manufacturing experience, we have fine-tuned

our production processes and techniques to ensure the highest

quality marine rubber airbags. Our extensive experience allows us

to deliver reliable and durable products to meet the specific needs

of our customers.

Customization capabilities

We understand that different marine projects have unique

requirements. Therefore, we offer customization options for our

marine rubber airbags to meet the specific demands of our clients.

Our team of experts works closely with customers to design and

manufacture airbags that perfectly fit their individual project

needs.

Quality assurance

Quality is our top priority. We have implemented a stringent

quality control system that covers every stage of production. From

selecting the finest materials to rigorous testing and inspections,

we strive to deliver marine rubber airbags that meet international

standards and exceed customer expectations.

Excellent customer support

We prioritize customer satisfaction and are committed to providing

exceptional support throughout the entire process - from initial

consultation to after-sales service. Our dedicated customer support

team is always available to address any inquiries, provide

technical assistance, or resolve any issues that may arise,

ensuring a smooth and hassle-free experience for our clients.